High Performance

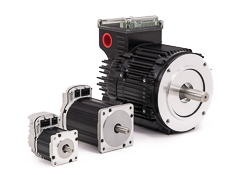

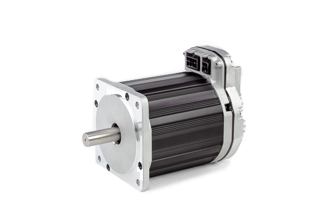

High Power in a Small Package

Attaining maximum usable power requires high peak torque, high continuous torque and high rated speed—the Hudson servomotor has all three.

- High peak torque is achieved by using sintered Neodymium-Iron-Boron permanent magnets—not plastic-bonded Neodymium—and by using advanced, 3-D finite element analysis (FEA) software to optimize magnet shape, winding fill factor, stator skew angle, and rotor geometry.

- High continuous torque requires a brushless motor that can manage heat. With its carefully optimized thermal design, Hudson servo motors dissipate heat with ease. Even when pushed hard, the Hudson’s 200ºC-rated winding insulation stays safe, and its specially-formulated permanent magnets are free from significant drop-off in field strength.

- High speed servomotor operation requires high frequency variation in motor current. The Hudson servomotor’s fast electrical time constant (low ratio of winding inductance to resistance) offers minimum impedance to these high frequency changes in current, so there’s minimum torque droop. High speed operation combined with simultaneous high torque gives you maximum power.

Responsive

High performance servo control—dynamic accuracy, velocity regulation and fast settling time—requires a brushless motor that is responsive, both electromagnetically and mechanically.

- The Hudson’s fast electrical time constant not only minimizes steady-state torque droop, it allows quick reaction to the fast transients demanded by high-performance servo drives.

- Fast mechanical response is accomplished by generating high peak torque with a low inertia rotor. With a high torque-to-inertia ratio, less torque is wasted accelerating the rotor, and more torque is available for accelerating the load.

Smooth and Quiet

Many servo motors that have high torque for their size are afflicted with high detent torque (the unenergized servo motor wants to lock onto certain positions more than others). They also often have significant distortion in their back-EMF signature, so even the best AC sinewave servo drives will unavoidably generate torque ripple. These torque defects cause vibration and noise, impair settling time performance, and induce servo hunting. Smooth, quiet motion requires a brushless servo motor with low detent torque, and linear, low-ripple torque output. Rotor balance and bearing quality are also very important, especially at moderate to high speeds.

Magnetic design can also greatly influence brushless motor noise and vibration. Over the last several years, it has been in vogue to use internal permanent magnet (IPM) rotor designs in servo motors in order to cut costs. The IPM design buries permanent magnets within a lamination stack on the rotor shaft so as to focus the permanent magnet flux. Flux focusing allows the use of smaller and/or lower energy magnets, however, it leads to large variations in the motor’s inductance as it spins, resulting in inferior servo performance. It also causes pulsating, non-tangential forces within the motor that cause significant audible noise and vibration.

- Hudson brushless motors use an external permanent magnet (EPM) rotor design for maximum smoothness and minimal audible noise. At right, see the graphs comparing the audible noise of the IPM design to that of the Hudson (EPM) design, and listen to an audio recording of an A-B comparison of the two designs.

- Hudson servo motors have obliquely aligned stator lamination teeth and permanent magnets with a carefully engineered cross-sectional shape to minimize detent torque. They also produce a harmonically-pure back-EMF which minimizes torque ripple.

- Each Hudson BLDC motor is shipped with a precisely custom-balanced rotor, and high quality bearings to ensure ultra-smooth mechanical movement.

- For designers used to using stepper motors, the Hudson servomotor’s smooth and quiet motion will be especially noticeable.

A 20dB difference in sound level is surprisingly noticeable. Press the play button below to listen to the difference between the two motors graphed above.

Versatile

The Hudson servomotor’s high power density allows it to fit where other brushless motors can’t, and its open-standard design lets you use Hudson servo motors with practically any servo drive.

- These brushless dc motors have a very high “Km” (motor constant) per unit volume so you’ll get maximum power for the size BLDC motor used.

- Minimal space is needed for cable routing or service loops because the single cable, single connector pigtail (select models) exits the brushless dc electric motor tangentially (rather than perpendicularly) in a recessed groove. This further improves the Hudson’s effective power to size ratio.

- Hudson servo motors use standard quadrature encoder feedback and 120-degree commutation sensors, meaning you can use them with virtually every make and model of brushless servo drive. You aren’t locked into using one vendor’s drive because of a proprietary feedback device.

- The Hudson’s brushless motor design eliminates the arcing, electrical noise, and carbon dust problems associated with brush motors. This makes them ideal in applications that are noise or dust sensitive.

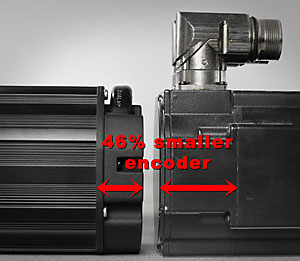

Hudson’s integrated, low-profile encoder takes less than half the space of the typical feedback device

Hudson’s unique, tangential-exit pigtail (select models) eliminates the large clearance required for the connectors on most motors

Rugged and Reliable

Designed for Rugged Reliability

Brushless servo motors are inherently more reliable than brush-type motors because: 1) they don’t have brushes to wear out or burn up at high power output, 2) the location of their windings allows easier heat dissipation, so the windings stay cooler for any given power output, and 3) the only moving parts in contact with each other are within the bearings. Even with these important reliability features, some brushless servo motors are more reliable than others:

- Hudson servo motors use oversized, precision bearings to decrease wear and to avoid premature failure when used in applications with radial (side) loading. The bearings are also permanently sealed with high-performance grease to reduce friction and motor noise, and eliminate bearing maintenance

- In all brushless motor stators, the windings at the ends of the stator are not in contact with the stator iron, and are therefore not as well heat-sinked as the more embedded windings. In Hudson brushless motors, we machine form these exposed end-turns, densely packing them, so that effectively they become a single thermal mass. This helps protect them against spot-overheating and burn-out.

- The neodymium-rich permanent magnets have a thick nickel-plating to be highly resistant to corrosion and hydrogen absorption which cause brittleness in rare-earth magnets and eventually lead to decrepitation (crumbling into powder).

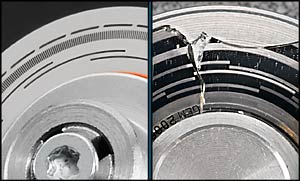

- The encoder disk is attached to the shaft using an expanding mandrel-type clamp that eliminates the set-screw failures common to many encoders. (This symmetric clamping method also reduces run-out error and improves rotor balance.)

- A built-in thermal sensor tells the servo motor drive when the encoder electronics reach their maximum safe operating temperature so that the brushless motor is protected from thermal damage. This sensor also ensures that the brushless motor windings stay a full 65ºC below their rated maximum temperature of 200ºC (most servo motor windings are only rated for 135-155ºC). This large safety margin protects against spot overheating which is hard for any sensor to detect, and it also reduces insulation failure due to the heat aging caused by prolonged operation close to the insulation’s short-term maximum temperature rating.

- The fully integrated optical encoder has unsurpassed noise rejection due to: 1) multiple, redundant optical apertures, 2) internal power supply filtering, and 3) a feedback-controlled illumination source. It also has a shatter-proof, photo-lithographically produced, stainless steel encoder disk.

- The balanced encoder runs cooler and is less load on the motor drive than most other balanced encoders because of its low current draw (40mA vs. a typical 150mA).

- Instead of having exposed, painted laminations, Hudson servo motors have an all-aluminum housing that is compression fit to the stator. This greatly improves conductive heat transfer to the mounting flange—the main source of heat sinking. The grooved housing improves convective transfer. Both features keep the BLDC motor cooler in any given application, thereby extending its life and improving its reliability.

- The brushless dc motor housing is anodized with a UV- and heat-resistant, “architectural quality” finish (not painted or powder-coated). This treatment preserves the rich, metallic look of the housing, and provides a sapphire-hard finish layer that resists scratches, and won’t ever peel, flake or chip.

- The entire Hudson servomotor family has been successfully tested for compliance with UL and CE certification standards. This means that Hudson brushless motors have earned the stamp of approval from independent agencies certifying that Hudson servo motors meet rigorous standards for electrical safety and electromagnetic emissions. Field audits every quarter by UL inspectors ensure on-going conformance with these standards.

![]()

Tested for Reliability

Every single Hudson brushless motor receives a full suite of in-line and post-production tests to assure you of the highest incoming quality. Among others, these tests include:

Electromagnetic performance

Magnet field strength

Encoder integrity

Rotor balance

Commutation sensor accuracy

Critical mechanical tolerances

Insulation system (hipot)

Complete functional test

HASS (Highly Accelerated Stress Screening) to test each industrial servo motor beyond its published specifications.

Reliability That’s Backed Up Like No Other Servo Motor

All Hudson motors carry a three year warranty. Actually, it’s even better than that. Teknic knows that machine components such as motors are sometimes stored in inventory for a while before being used, so we don’t start the warranty clock until you put the motor into service (up to a maximum of six extra months). Nobody else in the industry has a warranty that even comes close.

Hudson’s windings are tightly formed and laced to act as a single thermal mass to reduce hot spots. Tightly packing the windings also reduces wire vibration that causes acoustical noise and insulation failure.

Hudson’s shatter-proof disk is concentrically clamped to the shaft for better accuracy and reliability. Glass encoder disks can easily shatter, and set-screws are prone to failure.

Hudson’s architectural quality, anodized finish won’t chip or peel like paint and epoxy coatings.

Save Money—From Purchase Through Installation

Machine designers know that the total cost for any component in their machine is not just the purchase price alone. It includes the cost of any required peripheral components (e.g., cables, sensors, etc.), installation costs, engineering costs (making the component function as desired in the machine), and repair and maintenance costs. Hudson servo motors excel in all these categories.

Low Purchase Price

The purchase price for the Hudson family of servo motors is so low, you’ll wonder what the catch is. Here’s the secret (actually two secrets):

First, our OEM focus has allowed us to eliminate all the middlemen. If you’re an OEM, you can buy directly from Teknic, save all the typical distributor mark-up costs, and get 100-piece annual quantity pricing even when you buy individual servo motors. (You also get factory-direct technical support.)

Second, we’ve intelligently limited the number of industrial servo motor options. Limiting the options allows us to drastically reduce manufacturing expenses and put the savings into brushless motor performance, quality and lower prices. And while we may not offer as many options as some other motor manufacturers, we think the Hudson servo motors offer enough selection to give most of our customers the flexibility they need:

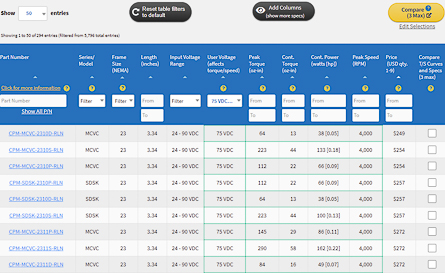

- Each brushless DC motor has three winding options, three connector options, two options for encoder output type, four choices for encoder resolution, and an option for IP66K/IP67 sealing (suitable for high pressure washdown). The NEMA 23 size servo motors have two shaft diameter options.

Whether you’re looking for a better, lower cost servo motor, or you’re looking for an economical, but high performance, replacement for a stepper motor, a Hudson servo motor will meet your needs.

Hudson Servomotor Features Save You On Installation Costs

A number of thoughtful design features will save you money during installation:

- The finished pigtail (or on-body connectors on sealed models) save labor compared to brushless motors with “flying leads” that have to be terminated and inserted into connectors. Wiring mistakes are also prevented.

- When an extension motor cable is needed in models with a pigtail, the Hudson’s convenient single-connector design saves you substantial money.

- Hudson’s standard configuration includes an encoder with high-current, low-impedance, totem-pole outputs. This robust interface virtually eliminates noise problems associated with commonly used open-collector encoder outputs, and uses fewer wires than differential encoders (saving money, and saving space in cable tracks). A differential encoder option is available for applications with very long cable runs or severe electrical noise.

Hudson’s zero-clearance pigtail (select models) can be routed in whatever direction you need to save the most space. Effective motor size is greatly reduced.

Hudson motors can be configured with either a finished pigtail or on-body connectors. No frustration with “flying leads”. (Souriau Trim Trio® connector shown; Molex Mini-fit, Jr. and M12, on-body connectors are also available).

Ensured Application Success

Teknic’s OEM-only focus means you’ll work with factory specialists who will create a solid-body simulation of your application (free of charge) to ensure you get the optimum brushless dc motor (not too big, not too small).

- Teknic will also create a custom torque/speed curve made specifically for whatever motor drive you plan to use (hopefully a Teknic servo drive, but Hudson servomotors are compatible with virtually any brushless servo drive).

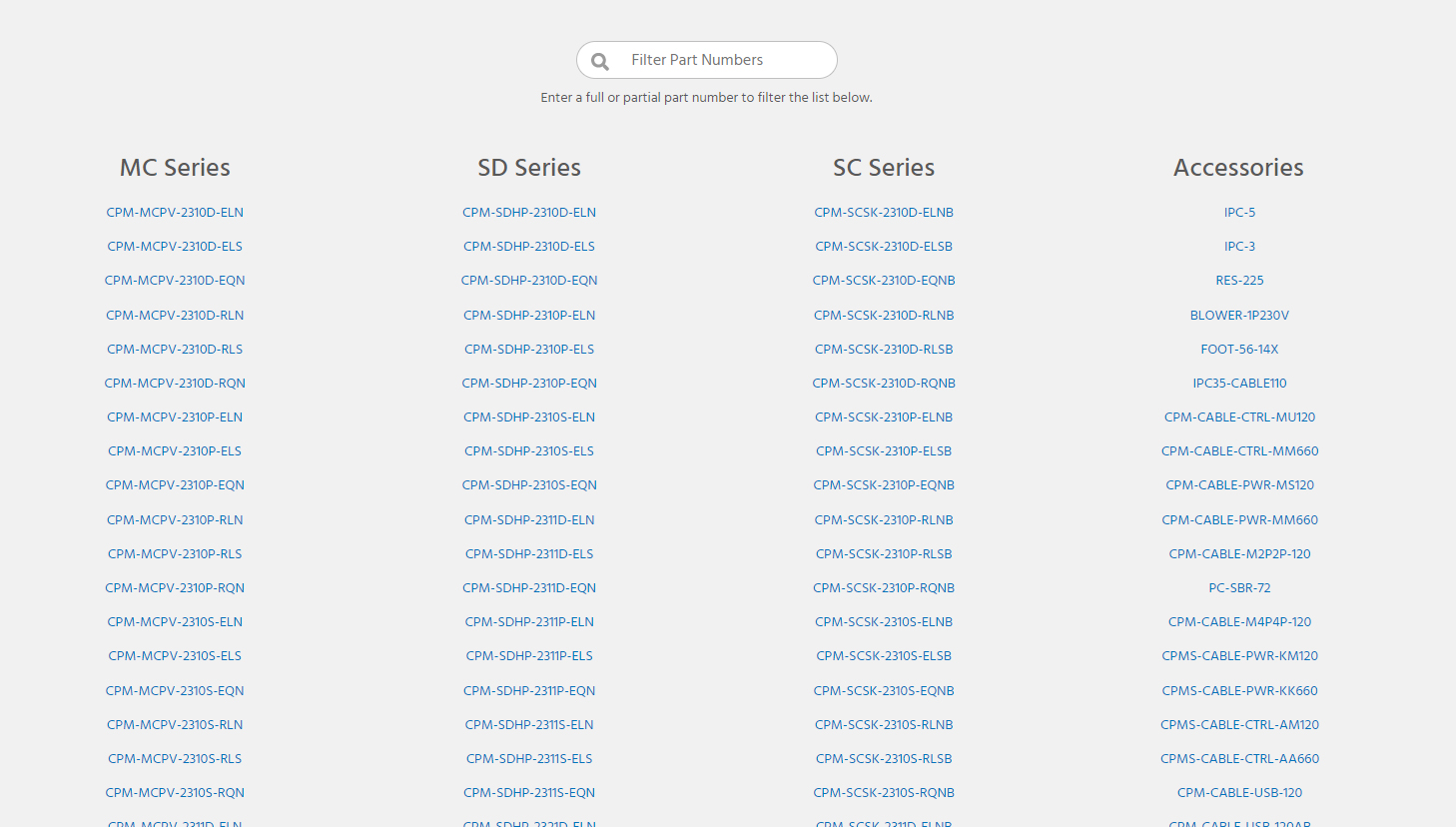

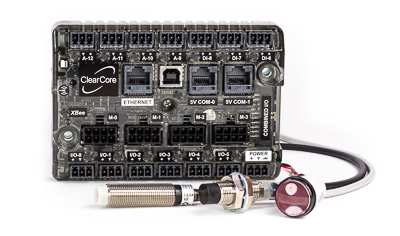

Looking for an all-in-one solution?

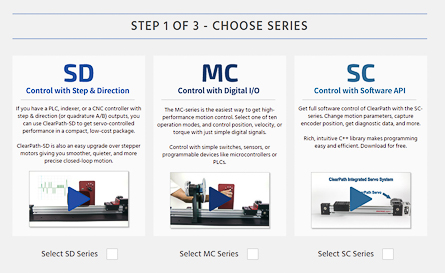

ClearPath is Teknic’s line of brushless servo motors with a built-in drive and controller. Simple, compact, and lower cost than the sum of its components.

For OEMs, Teknic will perform a free simulation of your application, and generate a torque/speed curve for the exact motor and drive you plan to use. This will give you complete confidence in the overall, combined performance of your chosen components.

What are the differences between a brushless motor, a brushless dc motor, a servomotor or even a brushless dc electric motor?

There is often confusion about brushless dc electric motor types because a number of brushless motor technology terms are often used interchangeably. Hudson motors have been called (more or less correctly) all of the following:

- BLDC motor, brushless dc electric motor

- Three-phase, permanent magnet motor

- Synchronous, permanent magnet motor

- AC servo motor (AC because electronic commutation requires a sinusoidal current to produce constant torque, not to be confused with AC induction motors)

- DC servomotor (presumably to distinguish them from AC induction motors)

- 3-phase servomotor or just servo motor

Technically speaking, all of Teknic’s servo motors are “3-phase, synchronous, permanent magnet, brushless, servo motors”. The term “servomotor” means that the BLDC motor is used with a feedback device (e.g., an optical encoder) to control torque, velocity, and/or position. The term BLDC or “brushless”, aside from the obvious, means that the motor requires a drive that supports electronic commutation. The term “permanent magnet”, in the context of servomotor types, means that the brushless motor uses permanent magnets on the rotor (or on the stator, in the case of brush-type motors). The term “synchronous” means that the rotational speed of the electromagnetic field is the same as (synchronous with) the speed of the rotor; there is no “slip” between them. And, finally, the term “3-phase” means the servomotor has three separate stator windings (connected together in a delta or wye configuration).

Stepper motors (or, stepping motors) are also brushless, permanent magnet motors. They are generally 2-phase or 5-phase motors. Stepper motors are not typically servo controlled, although their position is sometimes checked with an add-on rotary encoder after the end of each move to correct for lost steps or stalls. Stepper motors are commutated by rotating the electromagnetic field in incremental steps (typically 200 full steps per revolution) and allowing the rotor to “catch up” with it.